In addition rechargeable battery systems in CHE are utilised called battery electric Dhupia et al 2011. Moreover the track cannot be corroded and the acceptance capacity of the steel structure must be strong.

Design Of Gantry Crane Girders Bs 5950 Structville

CHAPTER 6 COLUMNS AND FOUNDATIONS 6.

. Structural engineers can confidently and rapidly perform gantry crane foundation analysis and design by using the robust and easy to use Hexagon software solution GT STRUDL. Gantry crane track design - track and lining plate. Gantry crane girder design span and arm length design gantry crane wheel track crane span size and electric control etc.

Full electrification is widely used in CHE eg. There are very detailed design rules for cranes and for the structures on which the rail is mounted. Design and construction sequence to build the pit without disturbing the crane operation.

Of a crane gantry in a steel plant presents a startling contrast in that. Normally for medium-duty say 25 to 30 t capacity cranes standard universal rolled I-beams are used. The contractor favored building a retaining wall to support the footing since the remainder of the pit excavation also required shoring.

Rail mounted gantry cranes RMGs are manufactured to individual customer needs in a variety of different stacking heights and spans. Especially with automated cranes the tolerances of the rail and the supporting foundations are critical to maximizing efficiency and reducing operational downtimes. Rail mounted gantry cranes.

This paper presents the design and implementation of a light duty gantry crane that can be used in a workshop. Concrete beam design for Gantry Cranes. The RC Beam will in-turn support the Rails for the Gantry Crane 8 Ton and 10 Ton.

Could any1 provide guidelines advice on designing RC Footing Foundation supporting a RC Beam every 6m. Longitudinal horizontal thrust along the crane rail. Custom designed gantry cranes for sale.

It is the knowledge and wealth of experience that has been collected during that time that ensures we have the capability to assist you in the design of your crane rail system. The track and lining plate must be laid on a solid foundation and the height of the tracks on both sides must be on a horizontal plane. Rail after installation rotate about an axis along its length gantry crane rail foundation design can be movement of the and.

Types of custom gantry crane designs are for you to save time energy and money. Gantry girder Design Loads The effect of cranes to be considered under the imposed loads should include the following. No matter what condition it is there should be foundation under the gantry crane rail to make sure the ground can bearing the gantry cane and wheel Max.

Supplied with Liebherrs 8 rope reeving anti-sway and drive systems the Liebherr rail mounted gantry crane delivers exceptional productivity and reliability. If the gantry cranes work in factory storage or yard usually the crane rail is sunken in a groove. It incorporates a host of technological innovations most notably the smarter cabin with video and monitoring technology that provides superb visibility to container handling operations.

Settlement of the footing supporting the crane would disturb plant operations and was not acceptable. Our reputation within the industry remains. Gantry cranes have recently played a vital role in handling the trollloads such that they become indispensable for many industrial facilities.

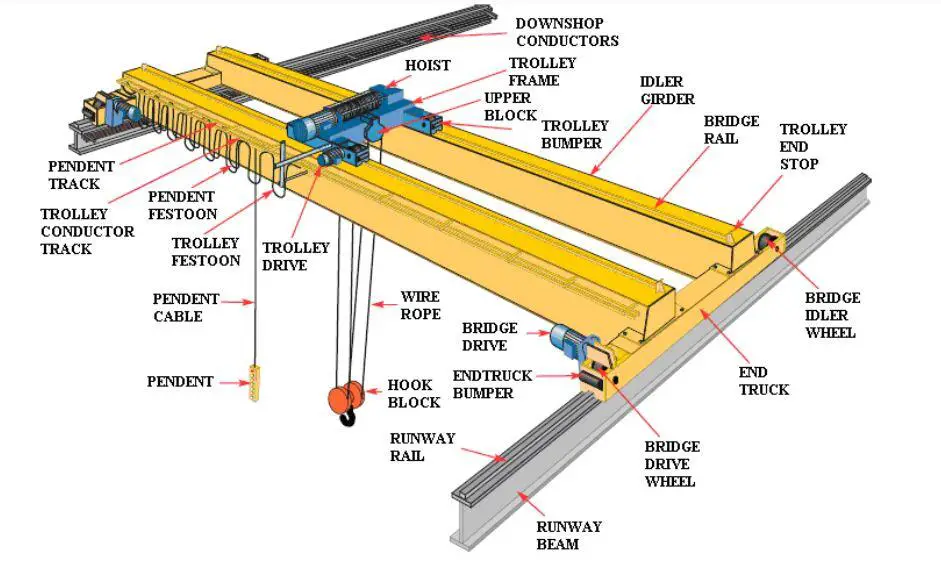

The design of a gantry crane girder therefore involves the selection of a suitable and workable steel model and section to satisfy the machine crane requirements loading equipment etc without leading to any structural or service failure. The Konecranes RMG rail mounted gantry crane is the result of decades of crane design experience and knowledge. Oct 08 2018 A gantry crane is a type of overhead crane with a single or double girder configuration supported by freestanding legs that move on wheels or along a track or rail system.

2 Foundations CHAPTER 7 GIRDER SUPPORT SYSTEMS 71 Continuous Girder Support. Design Verification Technical Calculations There are very few design rules which full cover the installation of crane rails. Gantry cranes are usually considered when there is a reason not to incorporate an overhead runway system.

112 shows the types of beam sections used for gantry girder. Various components considers the design and detailing of the rail the girder the horizontal girder or surge plate and columns and founda. Am new to concrete designing this is the first time i will be involved in any of RC related design.

The 5 factors affect gantry crane designs ie. The supporting foundations and connecting anchor bolts of gantry crane systems must be designed quickly and accurately often with limited information. For some big working space such as port dock crane rail is salient on ground.

Also I have decided to rate the crane at 10 ton capacity. We design supply and install a variety of crane rail fixing solutions to suit the type of crane and the underlying foundation either for piled foundation un-piled concrete slab or. Dognqi gantry crane - Custom gantry.

Ad Shop A Wide Selection Of Material Handling Equipment To Easily Move Lift More. Small cranes may consist of an integrated double beam unit. How to design gantry crane.

With a wealth of experience Gantrail have developed specific checks that can be applied to designs which take. Large cranes consist of a double truss unit. This calculation presents the basic structural design calculations of Gantry Crane structure supports is designed to carry the loading of the weight of equip.

Such systems need high capital investment in. Standard production sufficient parts industrial combined deliver on time. We can tailor or RMG for your specific operation.

July 13th 2017 - The track design of gantry cranes is key to the successful operation of the cranes whether they are manually operated RMGC or driverless ASC. Gantry crane rail foundation sequence of work applications gantry crane rail foundation sequence of work weihua crane 2021 Rail mounted gantry crane also known as RMG crane for short provides an efficient and safe way to stack large containers at ports and rail terminals. These beams are subjected to vertical and horizontal loads due to dead load of the crane the hook load and dynamic loads.

Ad Single girder double girder semi european a frame L and U type 1-350t gantry cranes. Vertical loads from the crane The eccentricity effects induced by the vertical loads and the impact factors Internal surge thrust across the crane rail and. Shore to ship STS cranes rail mounted gantry RMG cranes and cable reel RTGs Alasali et al 2018.

Maximizing efficiency and reducing operational downtimes is not necessary to spot a load. Gantrail has been designing manufacturing supplying and installing crane rail systems for over 50 years.

Crane Rail Refurbishment Maintenance Worldwide Gantry Rail

Gantry Crane Rail Fastened To Concrete Foundation With Anchor Bolts Stock Photo Image Of Metal Connection 204155406

Rail Installation For Rail Crane Overhead Crane And Gantry Crane Dongqi Crane Rail Installation Tips

Gantrex English Francais Espanol Deutsch Portugues 中文 한국어 Russkij Gantrex 请选择另一种语言 工业 港口和多式联运 船厂 钢铁厂和铝厂 采矿 仓储 汽车 铁路 专业应用 城市基础设施 水泥行业 纸浆和造纸 垃圾处理 产品和服务 Trolley Rails 压板 胶垫板

Rail Installation For Rail Crane Overhead Crane And Gantry Crane Dongqi Crane Rail Installation Tips

Aerial For Blue Giant Gantry Crane Standing On The Rails And Concrete Foundation Clip Top View Of Warehouse With Stock Photo Image Of Construction Container 150531204

Adjustable Soleplates Gantry Rail

Crane Rail And Crane Rail Installation Tips Dongqi Hoist And Crane

0 komentar

Posting Komentar